| |

Sample Technical

Sheet

|

All products on our Products

Page are supported with a user friendly technical sheet, written in plain

English. They describe uses of all the components where they are used, why you

should use them, and how to use them as well as much more.

Click

Here to access the Sign One Technical Sheets.

Provided below is an example technical sheet for one

of our products:

| |

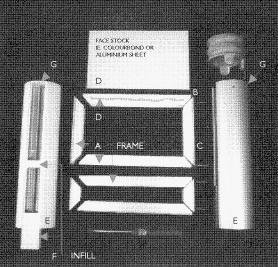

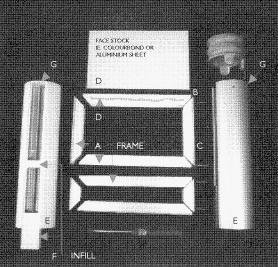

ITEM: P1485R

SIGN ONE POST 80mm ( 3 1/4" )

P1484R

SIGN ONE INFILL AND FRAME

DESCRIPTION: 80mm

( 3 1/4" ) post and frame step by step guide. See items individually for details on their

features.

CONSTRUCTION & ASSEMBLY GUIDE

No.1 - STANDARD FRAME:

|

|

| |

|

|

| |

Step 1 A. Cut frame to required length and mitre corners to 45o

Step 2 B. Notch back horizontal pieces to allow clearance

into opening recess (required for sliding into posts, not required when using frame

alone)

Step 3 C. Using the Vee groove in the back of the frame as

centre, drill hole to align with screw flute and using a metal thread 8 gauge screw

assemble sign frame.

Step 4 D. Cut face stock and allow clearance to slide into

post and then run a bead of suitable premium glue along recessed fin (see 4409RRR)

Step 5 Carefully place sign face to recessed fin and press

down firmly, cleaning off excess glue if required.

Step 6 E. Determine post lengths and cut

to size

Step 7 F. Cut the infills to required length, small

sections can be cut to provide spacers between sign panels " Hot Tip" If

you are concreting posts into the ground, cut a small infill and screw it into a position

level with the top of the hole. This will leave the bottom of the post open to allow the

concrete to flow into the cavity which enhances the installation and saves infill, whilst

also allowing removal of infill for cutting down to allow space when adding signs!

Step 8 Slide your finished sign frame into recess fin of

sign post and then slide in infill. Another " Hot Tip" is to again use a

small section of infill at the bottom of the post to close off and hold in place

assembled items. (for ease of assembly and transport)

Step 9 G. Using your selected cap, either screw flat cap to

top of post by utilising screw flute or press in cast aluminium cap into top of post

and drill post to suit cap prongs.

|

|

| |

APPLICATIONS: |

|

| |

|

|

| |

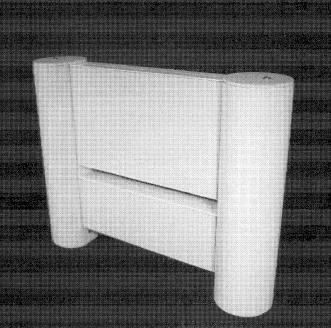

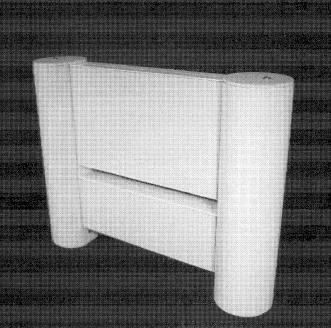

Finished assembled Sign One showing flat caps and multipanels, please note clear lines

with no gaps. This minimises cobwebs, spiders and insects, keeping your sign clean. Its

flat faces provide graphics in your chosen media – vinyl graphics, digital printing,

screen printing and engraving to name but a few. Engineers

Specification should be sought to ensure size/suitability of the system by the user, prior

to use.

GRAPHICS: Text and graphic techniques we recommend include

– pre spaced vinyl computer cut lettering. Premium brands screen printing, engraving

and plain infilling, photo etching, laser engraving and digital image printing. (see

4409EEE)

Copyright © Sign One Pty Ltd 1998

4409EE |

|

|

|