|

Installing a sign face to a Clipsin sign

frame

|

|

A step by step guide to installing your sign face or

banner to a Clips-in frame. |

|

|

|

|

Installing -

Safety First |

|

Staff experience

Ensure the suitability and experience of your staff and their

training to fabricate and install our sign systems prior to using.

Safety of workplace

Ensure you have evaluated the equipment for safety guarding and

your facilities are of a suitable type to work with our sections.

Personal protection

equipment

Please provide all necessary personal protection equipment to

your staff including ear protection and eye protection. |

|

|

|

|

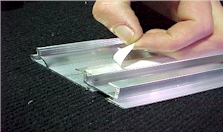

Remove double sided

tape liner |

|

Remove the liner from double sided

tissue tape . We are assuming here that the recommended double sided tape

has been placed on the rope slot on to the rear sloping section nearest to

the back of the base.

|

|

|

|

|

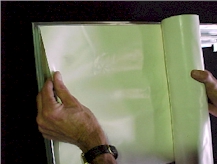

Sign face

positioning |

|

Roll up the sign face leaving around

1000mm (3’4”) to position the alignment of the sign face to the frame.

Align sign face with top edge and end of frame, ensure the the sign face

will run along the frame square and true.

|

|

|

|

|

Adjusting and tensioning sign face |

|

Press the sign face firmly onto the

double sided tape. The sign face is now ready to apply tension. Starting

in the middle of the bottom edge pull down not out over the tape. Only

minor tension needs to be applied.

|

|

|

|

|

Pre tension sign

face |

|

Now working on the sides repeat the

process.The aim is to finish with the sign face tight but not drum tight.

The desired affect is a taught wrinkle free sign face. Remember the caps

will apply an overall extra tension when in place.

|

|

|

|

|

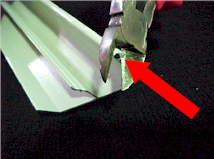

Remove excess sign

face |

|

If you have allowed additional sign

face, now trim the excess off to the outer edge of the frame. Place the

knife into the alum section and slide knife along slot to provide a safe

cut. This excess allows the sign face to be removed and reused at a latter

date.

|

|

|

|

|

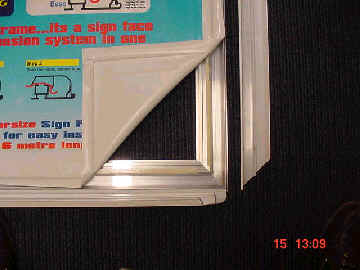

Installing the caps |

|

The caps have been trimmed or filed at

the extreme points of the mitre to allow a small amount of movement in the

cap relative to the base. Align the corner while placing pressure on the

cap.

|

|

|

|

|

Installing the cap

technique |

|

To quickly align the cap to the base try

marking the back edge with a saw cut, scribed line or marker pen. This

will assist on large frames as you can work from the middle of the frame

out. Single installers with like this time saver!

|

|

|

|

|

Closing the cap |

|

Using either hand pressure or a rubber

mallet start at one end of the cap and move along to the middle, then to

the other end of the frame.

|

|

|

|

|

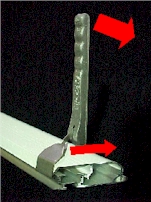

Removing the cap |

|

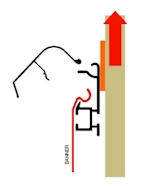

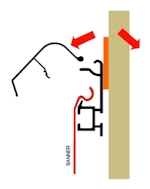

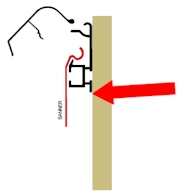

The Clips-in tool provide the sign user

an effective method of removing the cap. The front edge of the “clip”

hooks under the lip of the cap where it touches the sign face. The angled

part of the handles groove “hooks” onto the rear of the base. The

action is a steady pull away from the back of the frame. The tool applies

horizontal pressure to the cap releasing the trigger.

|

|

|

|

|

Resistance in the

cap |

|

The closing off the cap must be a smooth

unrestricted movement. If you encounter any resistance make sure the cap

is located in the base to form a free moving hinge.

|

|

|

|

|

Face positioning

tips |

|

In addition to double sided tape we

suggest various proven methods to make your face install easy.Plastic

clips and mini caps are detailed next.

|

|

|

|

|

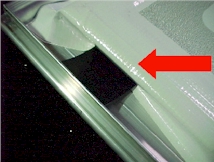

Face positioning

plastic clips |

|

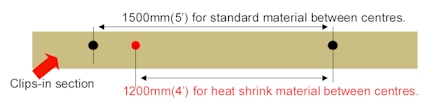

Plastic face clips can be fashioned from

plastic off-cuts, these simple clips can save time and simplify on site

installations. By inserting the clip into the rear of the base section

allowing the sign face stock to overlap the outside of the frame. Clip

into the rear fin against the grooves.

|

Recommended size is

36X36mm (1”3/8”x1”3/8”)

|

|

|

|

Face positioning

mini caps |

|

Small sections of cap can assist when

installing long sign faces. They can act as mini clips placed in positions

as a temporary holder.

|

Recommended size is 75mm (3”) long, use

off-cut cap. This size fits in your pocket easy.

|

|

|

|

Face positioning

tips “Vertical” |

|

Install the frame on a wall or the like,

then remove liner off double sided tape. Place sign face on the tape,

working around the sign face take up the wrinkles by pulling the sign face

outward to edge of frame.

|

|

|

|

|

Installing large

frames single handed |

|

When installing large oversize frame

make up 75x75x1.6mm (3x3x1/16”) alum plates with holes. Screw to the

rear of the frame with counter sunk screws. These plates can be used to

rope of to and hoist the frame into position from the roof. When frame is

in position, remove cap,fix with suitable fixing and replace cap. Then the

escutcheon plates can be snapped off or left.

|

|

|

Use escutcheon to lift sign in to position, remove

rope. |

|

|

Use escutcheon for fixing or snap off. |

|

|

|

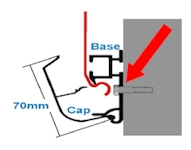

Hiding your fixings under the cap |

| The allowance of space inside the section give the

opportunity to hide your selected fixings. Remove cap from frame, then

install suitable fixing inside cavity. You will notice we have placed a

slight groove into the section for ease of alignment of fixings. |

|

|

|

|

Installing large

frames |

|

When installing large oversize frame to

difficult surfaces try using a suitable right angle alum section fixed to

the wall at the desired height. This allows the frame to be “hung” on

the now concealed bracket using a suitable fixing.

|

|

|

|

|

Fixing tips |

|

When fixing the frame on site use

appropriate fixings through pre drilled holes. Fix every 1500mmm (5’) or

less for flexible sign faces or every 1200mm (4’) or less for heat

tensioned materials.

|

|

|

|

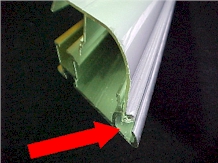

Security Fixing of Clips-in cap |

|

When installing large clips-in frames you will need to

ensure the cap is securely fixed to the base to ensure long term tension

of the sign face. On the back of the cap there is a groove in the

extrusion by installing a 30mm (13/8") screw through the cap, into

the base as shown this locks the cap in position. We recommend this for

sites where access may be a problem if maintenance is required.

|

|